Lack of Fusion, Root Concavity, and Other Welding Defects

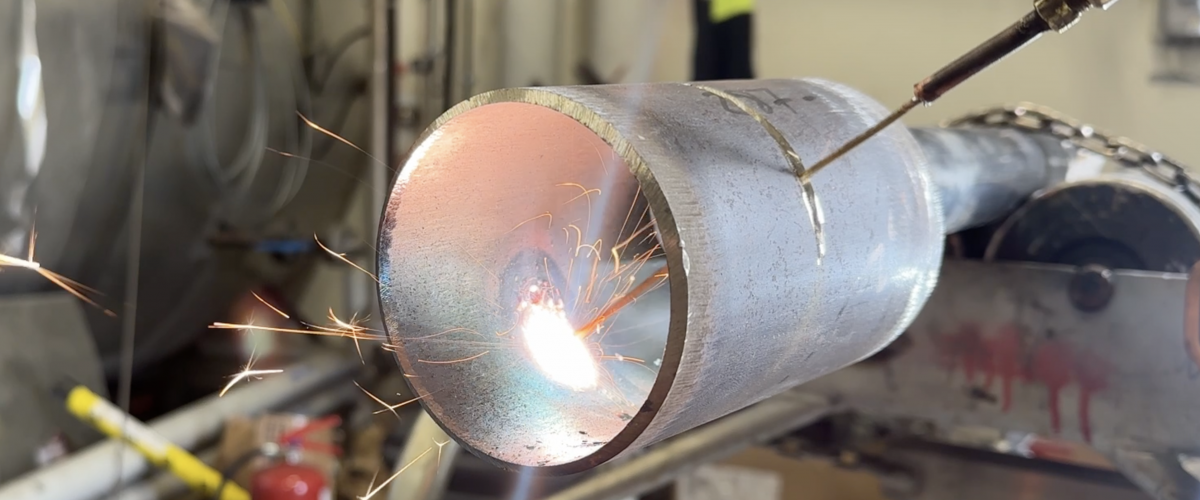

DIY Gas Torch for Fixing Lack of Fusion in 2mm Gaps – Welding in Hard-to-Reach Places

Background:

In 2017, our company, Pipeweld.ee, secured a contract to complete an 8 km heating pipeline in Sweden. The pipeline was challenging: a twin DN200 mm double-insulated pipe with a 6.3 mm wall thickness. Each pipe segment was 16 meters long and weighed over 2 tons. Installation was done using an excavator, and the welding was gas-welded using the 311 method as required by the client. The welds were 100% radiography (RT) inspected, Group B.

A single welder could complete 5 pairs of weld joints daily, totaling 10 welds.

Welders faced issues, which is inevitable in such conditions. Imagine the frustration when a tiny pore, lack of fusion, or root concavity was found on a 1 mm segment of an overhead weld in the 6 o’clock position or a lower weld in the 12 o’clock position. These areas were hard to reach, and sometimes both welds had to be cut open to fix even minor welding defects.

The pressing question arose: how to deal with defects like lack of fusion, porosity, and others quickly and with 100% certainty?

That’s how this life-saving nozzle was developed. And I’ll tell you upfront: I see no issue using it on larger diameters to fix welding defects.

Knowing how to fix these issues becomes easier with the right tools.

Welding Defects – How to Fix Lack of Fusion and Other Issues

In this article, we’ll dive into the design of acetylene-oxygen torches and create our own unique one, adhering to safety rules while eliminating lack of fusion and reducing weld repair time.

We’ll cover topics like:

- What is flashback, and why is it dangerous?

- Causes of flashback in a gas torch.

- How does an injector work?

- Testing methods for gas torches before use.

- Gas welding safety techniques.

- Designing your acetylene torch with these considerations.

- Assembling a custom torch for welding in hard-to-reach places.

- Testing the torch before welding the root pass.

- Notes on using the new torch for root pass welding.

- Other interesting tips on gas torches.

Weld defects in the root pass: What is flashback, and why is it dangerous during repairs?

Flashback is the ignition of the fuel mixture in the torch channels, potentially leading to the acetylene hose catching fire, which can result in an acetylene cylinder explosion!

To reduce the risk of gas cylinder explosion during fixing weld defects, safety flashback arrestors must be installed on both cylinders.

Causes of Flashback During Acetylene Welding and Fixing Weld Defects like Lack of Fusion, Root Concavity, and Porosity:

Every combustible material has its own burning speed. In our case, the speed at which gas exits the welding nozzle also plays a critical role. These speeds are crucial for adjusting the gas torch, ideally matching each other.

Main causes of flashback during welding and repair of welding defects like lack of fusion:

- The burning speed of the gas mixture exceeds the exit speed of the gas from the welding torch, and vice versa—this is the most common issue.

Other causes:

- A clogged nozzle, altering the calculated gas exit speed or causing gas mixture turbulence.

- Incorrect gas cylinder output pressure. Acetylene pressure should not exceed 0.2-1.2 bar, even if oxygen is supplied at 3 bar. Check the gas torch power and pressure ratio table for reference. Pic – 4.

- Incorrect torch ignition—mistaken adjustment of oxygen and fuel gas.

- Overheating of the welding torch nozzle, causing premature ignition of the gas mixture before it exits the torch.

- Excessive wear or improper use of the nozzle, leading to misalignment between the inlet and outlet holes. See pic 2.

- Barrel-shaped narrowing of the channel and converging nozzle—replace the nozzle. See pic 1.

- Shortening the channel exit section to less than 3 times the diameter of the exit channel—replace the nozzle. See pic 3.

Working of the Torch Injector

From the listed causes of flashback, the most important for us are:

- Gas flow speed (pressure setting in hoses + injector).

- Proper gas mixture ratio (injector).

Now it’s time to discuss the injector, which ensures the correct mixing of gases to avoid welding defects like lack of fusion.

Injector torches are designed to deliver low-pressure fuel gas (acetylene) into the mixing chamber by drawing it in with a higher-pressure oxygen stream.

This device is known as an injector, and the suction phenomenon is called injection.

Testing Methods for a Welding Gas Torch Before Fixing Lack of Fusion and Other Defects:

Before starting work with any new torch and nozzle, it’s essential to check the injector. This can be done with simple steps:

- Unscrew the acetylene hose from the torch, open the oxygen supply on the torch, fully open the acetylene supply, and place your thumb on the acetylene inlet nipple on the torch (where you just unscrewed the hose). Ensure there’s suction (your thumb should stick to the nipple).

- This suction indicates your injector is functioning correctly.

To be more precise:

- It has been established that the vacuum in the acetylene channels before the injector ranges from 35-275 mm Hg in an unlit torch and 25-50 mm Hg in a lit one.

Note: The noticeable pressure drop in a lit torch is likely due to the oxygen not being fully open during combustion, causing this difference.

What do you think?

Safety and Personal Responsibility in Gas Welding, Especially with a DIY Torch – IMPORTANT!!!

I’ve read plenty of literature on how acetylene torches work and what to focus on during their operation. I personally found answers to all my questions.

However, I can’t take responsibility for the conclusions you or others might draw from this material. You must understand that responsibility lies entirely with you.

Designing and Building Your Torch Following the Above Rules:

I’ve determined that the most important and delicate mechanism in a torch is the injector and the mixer that follows. So, if I want to create my own torch, I need to find a factory-made injector with a mixer and adapt my copper capillary to it, which is available at large hardware stores in Europe or online marketplaces. My tube is made of brass (an ideal material for torches of this type), with an outer diameter of 2 mm, a wall thickness of 0.5 mm, and a gas channel diameter of 1 mm.

After much experimentation, I found that if your brass tube is about 150-250 mm long, you can use an injector and mixer from a factory nozzle rated for 500 liters. The nozzle should be copper, which bends like this model:

R!MAC Svetsinsats till G11 Flexibel 500L. (Google it)

Cut off the copper tube from the torch, leaving 2-4 cm, solder your capillary to it, and voila—the torch is ready for testing.

Testing the Torch for Fixing Root Concavity, Lack of Fusion, and Other Welding Defects:

- Set the correct output pressure on both cylinders (see pic 4).

- Check the acetylene supply vacuum (methods described above).

- Perform the first ignition and adjust the flame to standard parameters.

- If you cannot achieve stable combustion and understand how to adjust a standard acetylene torch, the problem may be that too much solder has filled the inside of the copper tube during soldering, partially or completely blocking the gas flow. In this case, you’ll need to rebuild your torch.

- If you achieve stable combustion, you can begin a test weld for 1-2 minutes. After extinguishing the torch, touch the injector with your bare hand. If it doesn’t heat up during welding, your torch has passed the first test.

- Continue testing with longer welds, say 3-5 minutes. This was the final test for my torch because I knew I would use this nozzle for no more than 2 minutes to repair the root pass in a pipe. Since the pipe is an enclosed space where temperature rises faster, I decided to double the test time in an open environment.

- If your injector heats up to over 200 degrees, the risk of flashback increases. I measured more accurately to determine the injector temperature and welding time. Flashback occurs at 300 degrees. The operating temperature of a factory injector does not exceed 40-50 degrees.

Notes on Using a New Torch for Root Pass Welding:

Only when working with weld defects like root concavity and lack of fusion in the root pass through a welding gap did I sometimes notice a sudden flameout.

This effect didn’t always occur, but when it did, it was very pronounced. After many tests and assumptions, a 100% solution was not found, but ensuring proper ventilation in the pipe for better combustion is crucial.

Other Interesting Notes:

- Welding defects like lack of fusion, porosity, deep pores, root concavity, and other defects on any metal can be fixed using this method. Personally tested, but it does require skill!

- For proper torch operation, the nozzle’s exit channel diameter should match the mixing chamber channel diameter, while the injector channel diameter should be three times smaller.

- G2 and G3 type torches with any replaceable tip should draw air from the atmosphere through the open acetylene fitting at a rate not less than the nominal acetylene consumption at maximum oxygen pressure, as specified in the technical conditions for the specific torch model.

- The nominal acetylene consumption for each torch tip, as set out in the technical specifications for the specific model, should be achieved at minimum acetylene pressure and free flame combustion with fully open valves.

- Metal parts of torches should be made of brass, as it is ideal for withstanding the operational demands of gas torches.

Questions, suggestions, or comments?

Feel free to leave them in the comments section below this article. Your input is valuable, and I’m here to help you fix welding defects effectively, whether it’s lack of fusion, root concavity, or porosity.