Trenchless pipe installation: Horizontal drilling for pipeline installation and interesting nuances.

There is a technique called horizontal drilling, which is usually performed with very expensive equipment. However, this is not the only technique, and in many cases, alternatives can be found, including trenchless pipe installation.

Often, available alternatives are not offered by all contractors, but it is good to know that they exist.

Everything depends on the details of your drilling, such as the available space for the equipment, soil hardness, and other factors. All these nuances are not always apparent, so I recommend contacting several companies before making a decision.

However, it is good for the average person to be aware of the method of guided drilling within trenchless pipe installation.

It requires a smaller construction site for drilling but also a launch pit, whereas the horizontal directional drilling (HDD) method does not require a launch pit, but the equipment is larger and more expensive. The guided drilling method within trenchless pipe installation works in soils up to category 3.

How to reduce the costs of trenchless pipe installation

If the soil has a hardness up to category 3, costs can be reduced by using alternative, yet still professional, equipment.

We have often encountered the need to perform a drilling, for example, under a railway. When we compared price quotes from local companies using expensive equipment, we found that the prices were not satisfactory. This led to the need to seek alternative techniques for horizontal drilling.

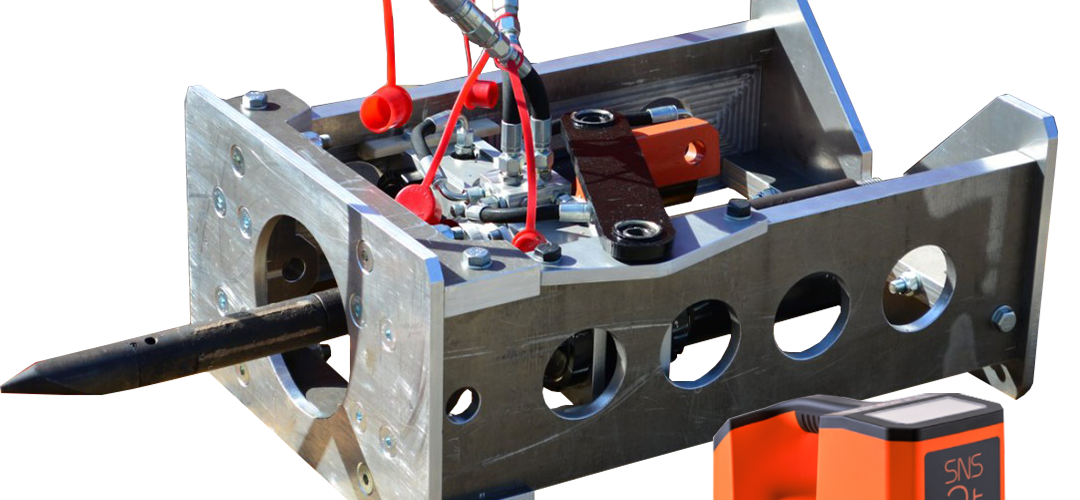

This is what the expensive equipment looks like:

Since 2018, we have successfully collaborated with the company Mempex.by, which since 2001 has been developing various equipment for trenchless pipe installation.

Installations for high-precision horizontal straight-line auger drilling under laser system control. Installations for guided drilling in plan and profile of soil under control of localization system. Equipment for trenchless pipe replacement (sanitation by breaking the soil) both with retained and increased pipeline diameter. Auxiliary tools and devices that facilitate the work of builders and ensure safe execution of the work. Mempex has several patents on its equipment, and their approach is truly impressive. The company invents, designs, and manufactures quality equipment.

To briefly describe the drilling process, you need to dig a start pit to the drilling depth, set up formwork around the perimeter of the start pit, and then lower the UM-20 installation, which drills up to 160 mm over a length of 60 meters with a weight of only 114 kg. After that, the magic begins.

Although the installation looks much simpler compared to Scandinavian equipment, it performs the same work and costs half as much. Moreover, the drilling is guided both in plan and horizontally.

Such a technical marvel is manufactured by specialists from Belarus.